Our semi-industrial facilities make it possible to define and scale biotechnological processes, reducing the risk of technological scaling and allowing us to validate and adjust the operating parameters of the processes.

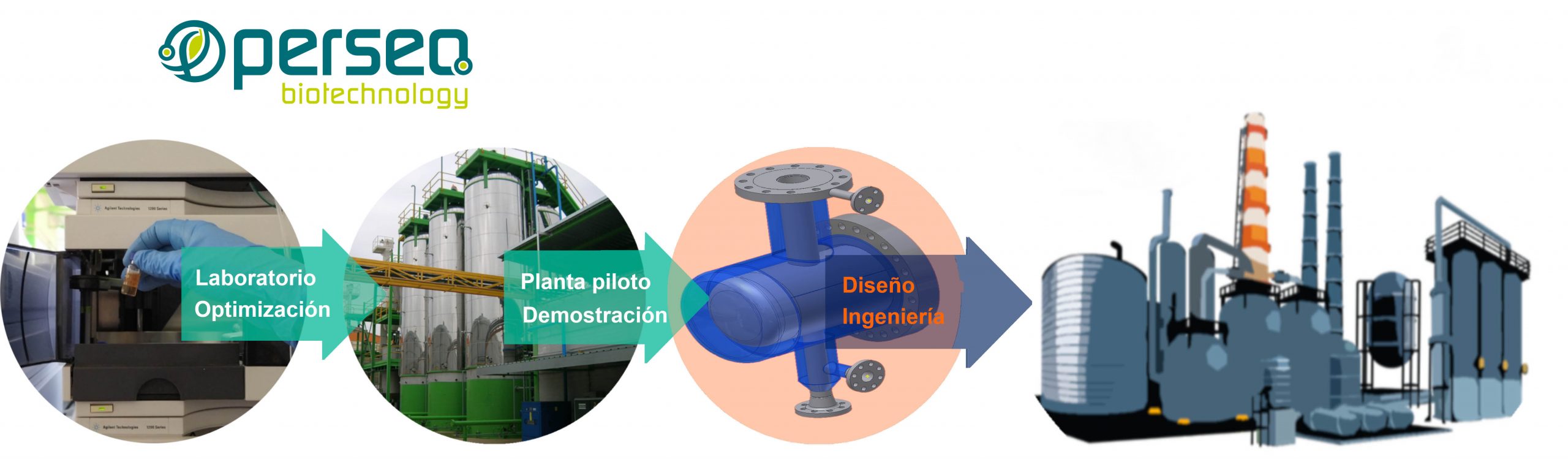

Due to our expertise, we can optimise processes associated with organic waste from the laboratory stage to scaling and demonstration at an industrial level.

This allows us to:

- Optimise engineering design parameters to ensure that projects meet the necessary technical and operational requirements.

- Adjust the operating and investment costs of industrial projects, improving their techno-economic viability.

- Reduce the technological risk of industrial scaling by having industrial processing equipment available.

- Develop projects for ourselves or for third parties under controlled conditions, from the laboratory to industrial implementation.

- Direct projects towards industrial viability, considering all the technical and economic factors of the process.

Semi-industrial plant (25 t/d)

Our automated semi-industrial plant with a capacity to process up to 25 tonnes/day of organic waste and by-products is designed to adapt to the specific needs of each project. With a wide variety of modules, we can carry out each of the required processes individually or together, as required by the operating conditions.

- Operational flexibility: The units can operate continuously, maximising process efficiency, or independently, allowing for detailed and segmented control.

- Variety of modules: Equipped to cover all stages of the process, guaranteeing quality and precision at every step.

- Versatility of raw materials: We have several processes that allow us to work and deal with raw materials of different characteristics and origins.

Our plant:

- Raw material reception unit.

- Physical and thermochemical pretreatment unit.

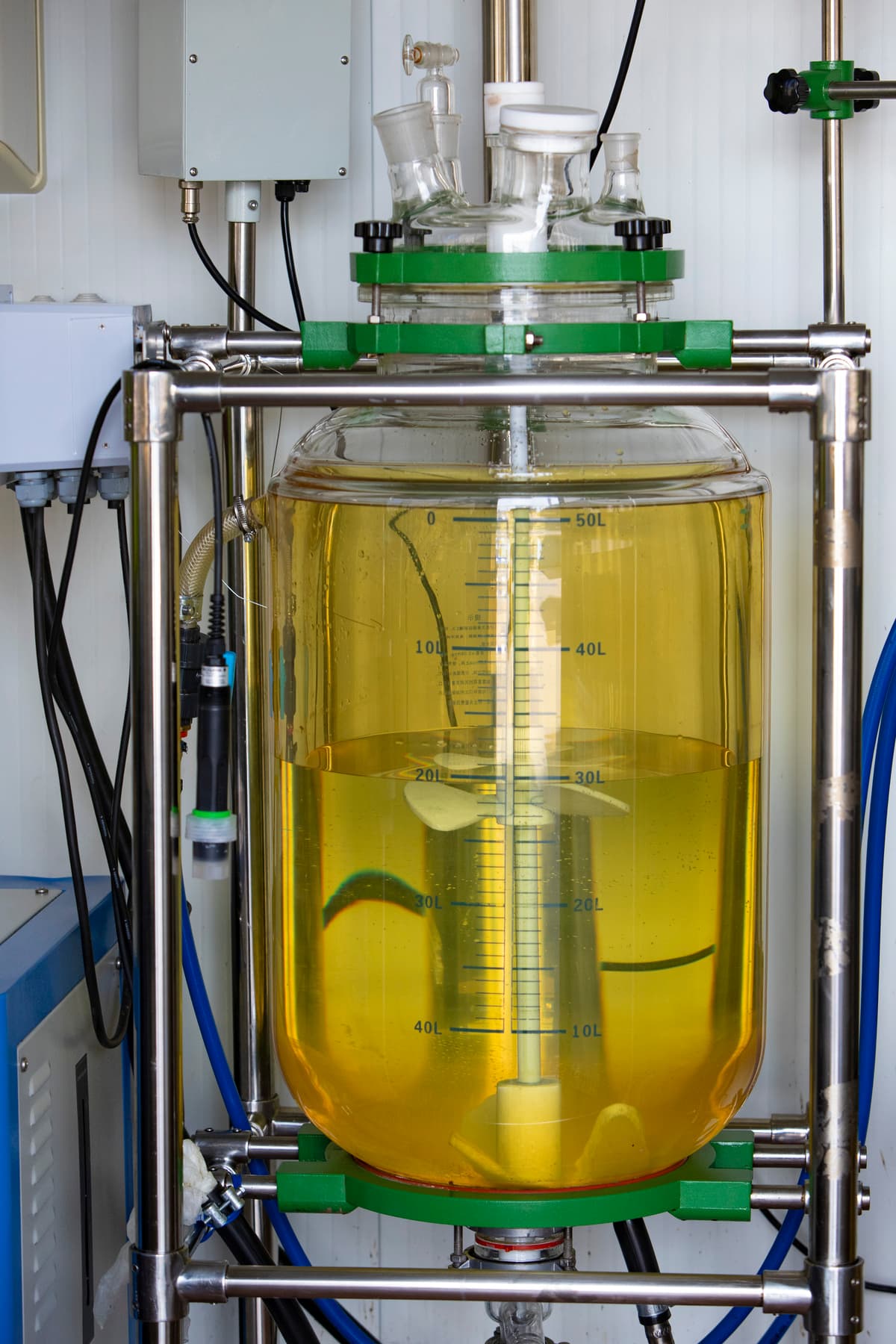

- Unidad de hidrólisis y fermentación (10, 20 y 50 m3).

- Solid-liquid separation unit.

- Distillation unit.

- Anaerobic Digester (2 m3).

- Capture and compression of CO2.

- Sistema CIP (limpieza in situ).

Our plant not only provides a controlled environment for experimentation, but also allows innovative techniques and technologies to be validated under real conditions. It is the ideal space for transforming ideas into scalable processes with verifiable results.

Laboratories

Our facility has specialised laboratories designed to carry out biotechnological and physicochemical tests and analyses. These laboratories offer advanced capabilities for working with volumes of up to 50 litres, providing optimal solutions for both research and for the control of pilot and industrial processes.

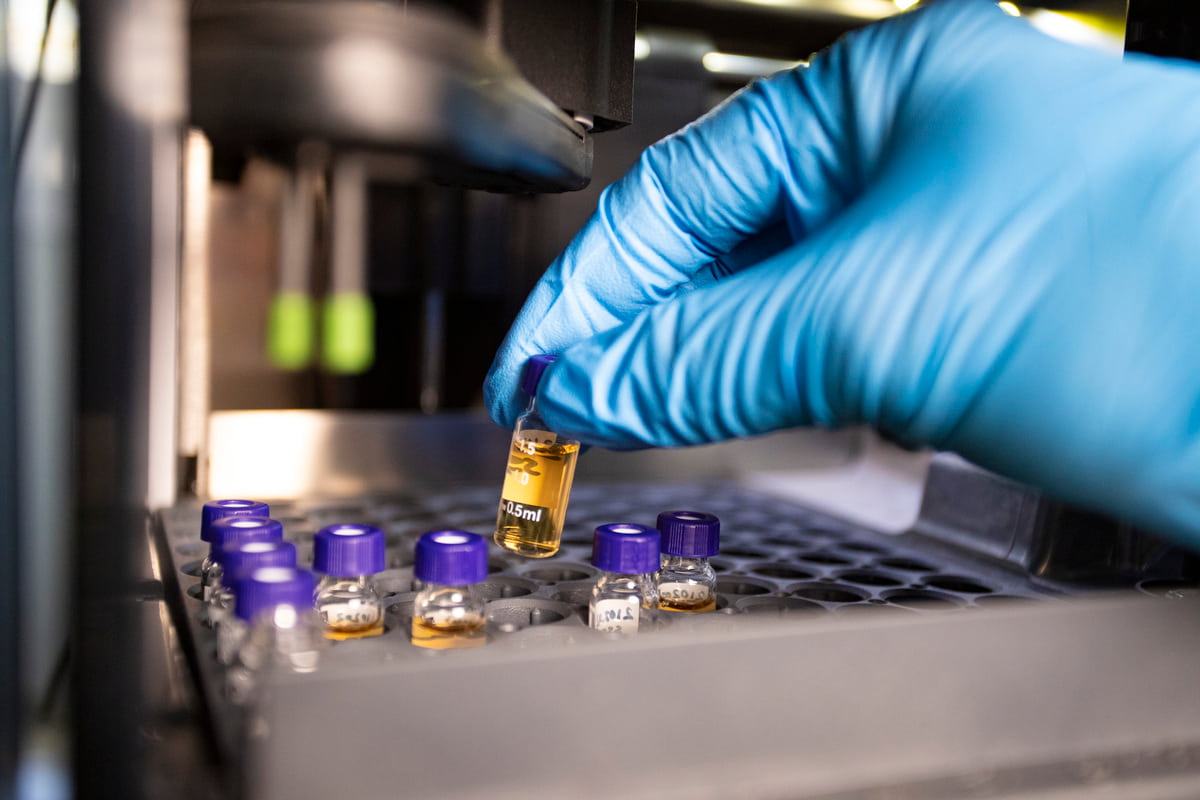

- Versatility in analysis: Suitable for a wide range of raw materials and physicochemical and biotechnological tests.

- Scalability: Ideal for initial developments that require a transition from laboratory to pilot and industrial production levels.

- Regulatory compliance: We operate under strict quality and safety standards.

Our laboratories:

- Conditioning and compositional characterization of raw materials/biomasses.

- Optimization of biotechnological processes.

- Physicochemical pretreatment processes.

- Enzymatic hydrolysis and fermentation processes up to 50 L.

- Distillation equipment.

Our team of experts is ready to accompany you at every stage of the process, ensuring reliable and personalised results that meet the needs of your project. If you are looking for innovation and precision, our laboratories are the ideal place to transform your ideas into tangible results.